2019 the TroPro trade exh…

Release Time:2022/05/25 Blog Browsing Times:232

The basic principle of laser cutting is to irradiate the workpiece with a focused high-power density laser beam to make the irradiated material melt, gasify, ablate or reach the ignition point quickly, and then blow away the molten part of the material with coaxial high-pressure gas or metal vapor pressure. With the relative linear movement of the beam and the material, the hole continuously forms a slit with very narrow width, so as to complete the cutting.

Laser cutting is a kind of non-contact processing, which has high cutting efficiency, fast cutting speed, small heat affected area, fine and narrow incision, parallel and smooth on both sides of the cutting seam, and can cut metal, non-metallic composite materials, leather, wood and other materials.

The laser cutting machine is operated by the laser control system. As a precision machining method, with the help of the control system, it can realize complex machining such as precision cutting and multi-dimensional engraving.

Due to the limitation of laser power and equipment volume, the thickness of laser cutting materials is different. With the increase of cutting thickness, the cutting speed will decrease significantly.

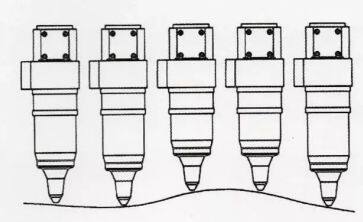

Servo system When processing curved surface materials, the processing height in different places is slightly different, so the size of the light spot gathered in different places is different, the power density is also different, and the laser cutting quality at different cutting positions is very inconsistent, which can not meet the quality requirements of laser cutting. Therefore, a servo system is needed to keep the relative distance between the laser head and the processing material unchanged at any time. The follow-up system of the cutting head can ensure that the height of the cutting head is consistent with that of the cutting material, so as to ensure the cutting effect.

Auxiliary gas Auxiliary gas suitable for the material to be cut must be added in the cutting process. In addition to blowing away the slag in the slit, the coaxial gas can also cool the surface of the processed object, reduce the heat affected zone, cool the focusing lens, and prevent smoke and dust from entering the lens seat to pollute the lens and cause the lens to overheat. The selection of gas pressure and type has a great influence on cutting. Common gases are: air, oxygen, nitrogen.