2019 the TroPro trade exh…

Release Time:2022/04/28 Blog Browsing Times:265

As the laser technology becomes more and more mature, the price of laser equipment is also falling all the way

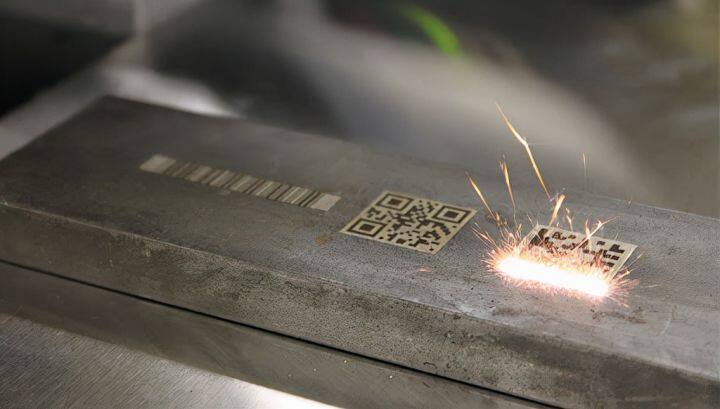

Ten years ago, laser marking was still a fashionable gadget. Most of the products that can use this technology are high-end electronic products. Today, laser marking has already stepped down from the altar and entered the homes of ordinary people, and its figure can be seen everywhere

After taking off the high-end coat, laser marking has become a new choice for more entrepreneurs. At present, a brand-new domestic laser marking equipment can be bought for only more than 10000 yuan. Behind the popularization of technology is the rapid development of technology and the catch-up of business competition.

Compared with traditional marking methods, laser marking has many advantages

Laser marking materials have a wide range of adaptability, from flexibility to rigidity, from high reflection to high absorption. They can be processed well whether metal, wood, acrylic or plastic

The precision of laser marking is high. At present, the mainstream marking equipment on the market can control the precision below mm. The text with thick and thin hair can be clearly displayed like laser marking;

Laser marking is not worn and cannot be modified, and the anti-counterfeiting effect is first-class. Because laser marking is completed by evaporating the surface of the material, it has the effect that can not be changed after processing. Similarly, the products after laser marking are also worried about wear and aging.

Laser marking is more intelligent. Laser marking equipment is generally operated with its own control system, which can usually achieve automatic operation. Even if the processing scheme is changed, it can be completed in only a few simple steps, which is convenient and flexible.

The selection of laser marking machine mainly depends on the three core parts: laser, control card and laser head.

Laser marking machines include ultraviolet laser marking machines, optical fiber laser marking machines, CO2 laser marking machines, etc. However, the main difference between different types of laser marking machines lies in the laser, and the structure is similar. Therefore, we mainly focus on the three core components when selecting.

Laser is the most important part of the whole equipment. Its light output effect directly affects the quality and stability of processing. Different types of lasers have different service lives, corresponding wavelengths and processing materials. Among the domestic brands, the more famous ones are Han Zu, Ruike, Chuangxin, etc.

The control card is the control system. Pay attention to whether it is encrypted. Generally, if the payment is not paid, it will lead to encryption, and subsequent use will have to pay again for decryption.

The professional name of laser marking head is laser scanning galvanometer, which is also an important factor affecting the processing quality. At present, the competition between domestic brands and foreign brands is fierce and the number is large, so I won’t repeat it one by one here.

In addition to the core components, laser marking equipment also needs good-looking after-sales maintenance.

Due to the limited service life of the laser itself, we usually need to replace and maintain the laser marking equipment after we buy it. The importance of after-sales service is self-evident. Here, it is also recommended that you try to choose a brand with guaranteed after-sales service.