2019 the TroPro trade exh…

Release Time:2021/08/12 Blog Browsing Times:1206

Why do laser equipment need antifreeze in winter?

Affected by the low temperature environment in winter, when the laser equipment is operated or stored at a temperature lower than 0 ℃, the laser and water-cooling pipeline will freeze, and the volume will become larger after water solidification, which will lead to the rupture or deformation of the internal pipeline of the laser and water-cooling system. If the cold water pipeline is broken and started up for operation, it may cause coolant overflow and damage to relevant core components. In order to avoid unnecessary losses, please take correct anti freezing measures.

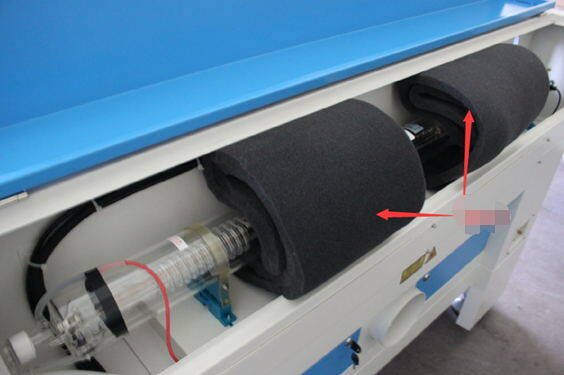

Laser tube

The carbon dioxide laser tube is water-cooled. We’d better control the temperature at 25-30 degrees, because the energy is the strongest at this temperature.

When the Laser tube works in winter

1. Please add a certain proportion of antifreeze to prevent the circulating cooling water from freezing. As the antifreeze has certain corrosivity, according to the use requirements of the antifreeze, according to the instructions of the antifreeze dilution ratio, dilute it and then add it to the chiller for use. Customers who have not used antifreeze can ask the dealer, and the dilution ratio depends on the actual situation.

2. Do not add too much antifreeze into the laser tube. The cooling layer of the tube will affect the light quality. For the laser tube, the higher the use frequency, the more frequent the water change frequency. Otherwise, impurities such as calcium and magnesium in purified water will adhere to the inner wall of the laser tube and affect the laser energy. Therefore, it is necessary to change the water frequently in summer or winter.

After the laser tube works in winter

1. Please drain the cooling water. If the water in the tube is not drained, the cooling layer of the laser tube will freeze and expand, expand and crack the laser cooling layer, resulting in the failure of the laser tube to work normally. In winter, the freezing crack of the cooling layer of the laser tube is not within the scope of replacement. In order to avoid unnecessary losses, please do it in the correct way.

2. Air pump, air compressor and other auxiliary equipment can be used to drain the water in the laser tube. Customers using water chillers or pumps can remove the water chillers or pumps and place them in a room with high temperature, so as to prevent freezing of water circulation equipment, damage to chillers, pumps and other parts, and bring you unnecessary trouble.